By Clair Purcell / June 9, 2022 9:32 pm

Like many adventures, it started as a conversation between strangers at the back of a bus.

I was at the Ferment Conference heading to check out Ginkgo Bioworks’ foundry, speaking to Bre, the Research Operations and Outreach Director from New Harvest, which I’d later discover is the leading field building organization for cellular agriculture.

‘There’s not enough B2B businesses in cellular agriculture. Everyone wants to be the one making the chicken nuggets…’

My ears perked up. One week into my new role as Chief Venture Builder at Innovation Lab, I was working out how to scale Innovation Lab’s new business-building capabilities, particularly ones that will have a positive impact on planetary health. What I love about intentional business-building is that there are so many impactful opportunities that aren’t noticed by entrepreneurs because they’re not as trendy or visible as… chicken nuggets.

The time is right to build infrastructure businesses to scale cellular agriculture.

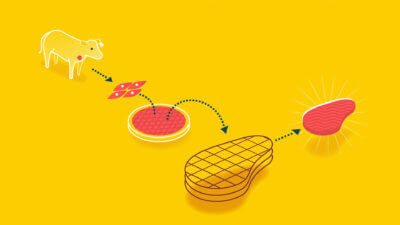

It was the start of a deep dive into the space of growing animal products without the animal–otherwise known as lab-grown or post-animal production: real beef and leather without killing a cow and real milk without milking one. It’s a wonderful, hugely impactful, and extremely complex industry that has the potential to eliminate 10-14 gigatonnes of carbon emissions per year, eradicate animal abuse, and deliver nutritious, high-quality meats, clothing, and ingredients to humans in a sustainable way.

The cellular agriculture industry is on the cusp of mainstream adoption:

- The science is shifting from proof of possibility to a focus on cost reduction. Inventors in this space have come a long way from the first lab-grown burger, which cost a whopping $400k. Even if you’re a skeptic on the claims of today’s companies making it for ~$7/kg (or ~$1.50/burger), the downward trend line is clear. Large infrastructure companies focused on delivering single pieces of the puzzle at scale for multiple customers will further push these techno-economics downward.

- Around the corner from cost reduction is scale. Today’s businesses will need to scale at 70% per year, every year for the next 10 years just to capture 1% of the global meat market. Early entrants by necessity are vertically integrated. New entrants need an ecosystem that helps them focus on their unique value proposition, not reinvent the wheel on the infrastructure needed to do so.

- Only 40% of the companies in the field today are B2B businesses. For capital-intensive industries like hardware and biotech, this is usually closer to 80-90%. B2B businesses have a lot of catching up to do to enable the level of scale needed.

- Regulatory approval is on the (far?) horizon. Singapore was the first country in the world to regulate serving lab-grown meat, with many others tipped to follow. This includes the U.S., who has partnered with the FDA and USDA to work through how to regulate.

- Growth in investments has increased dramatically ($1.3BN in 2021, up 336% from 2019). This indicates a broader recognition by the investment community of the dynamics discussed above and potentially smoother pathways to raising capital for large infrastructure projects.

- Reinvention of the way we make animal products has only just begun. We’re only just beginning to explore the areas where the cellular agriculture approach could be applied. A single application could upend an entire industry (e.g. palm oil, baby formula, and commodity foods like chocolate). If the natural resources and ethical constraints around certain foods are removed, we might see an uptick in the diversity of food options (lion steaks or tiger tacos anyone?).

Thousands of businesses need to be, and will be, built in this space over the next decade.

For that to become a reality, B2B businesses that make it easy to build new CellAg products will be fundamental.

Over the past month, we’ve explored where B2B businesses will be most impactful in reducing today’s cost of beef per kilo, from ~$22,000/kg down to something cost competitive. We believe there are four key focus areas:

- Optimizing bioprocessing & production systems. Creating proteins through cell culturing and precision fermentation is fraught with costly and inefficient processes that will be challenging to scale. We’re exploring how this can be improved by examining closed-loop systems, decentralized production facilities, and improving hardware infrastructure.

- Software and toolkits that enable simplicity in bioprocesses. Most companies develop their own software and toolkits out of necessity to effectively operate their bioprocess equipment. Building out standardized and simplified software toolkits will enable production cost reductions, the output of better data, and automation within a given bioprocess flow.

- Alternative manufacturing for proteins and inputs. The majority of cell ag production processes involve cell culturing or precision fermentation. This opportunity area explores alternative manufacturing methods, such as molecular farming, yeast, and microalgae, and examines opportunities with cutting-edge technologies around 3D printing and scaffolds to create proteins and inputs more cost-efficiently.

- Platform technologies for optimized ingredient discovery. The ‘holy grail’ of synthetic biology is to develop platform technologies that make the production of high-quality materials faster, cheaper, and more sustainable. This opportunity area investigates whether functional edible and non-edible proteins can be developed through platform technologies that can lend to applications within, and outside, cellular agriculture.

Big businesses need a strong ecosystem to be successful.

Venture Studios are powerful mechanisms for growing businesses that can impact entire ecosystems. This is because they:

- Build the businesses that need to be built. What is most impactful is often not the most visible, hyped, or attractive. Venture studios start from a market need and develop concepts in response to that need.

- Derisk concepts early. Often, lone founders can spend months or years working on a concept only to discover that it doesn’t work. Our venture building approach (a mix of lean, design, and agile methodologies with our own sprinkle of deep tech learnings) and access to industry pilot partners and experts means we learn early and cheaply what will be successful. We make fewer mistakes and move faster towards the right solution.

- Scale quickly. An early-stage startup needs to focus on two things: product validation and market fit. InnoavtionStudio provides the mental and physical space to focus on what matters most in the crucial first 18 months of a new company’s life. Operations, recruitment, funding, branding–these are all things the InnoavtionStudio team has been doing for years for our own company and the startups we support. InnoavtionStudio’s Brooklyn location has a brand new BioLab and we are actively exploring building out biotechnology-specific infrastructure in 2023.

- Build the dream team from the ground up. From the selection of Founders-in-Residence to headhunting CEOs or acting as the founding team ourselves, we build curated teams of people who are passionate, talented, and have the experience to scale up, not just start up. We‘re also proud to provide stipends and early funding to ensure that working on an early-stage startup is an accessible option to people from all walks of life, resulting in more diverse, successful teams.

All of this amounts to better chances of success; businesses built by Venture Studios are more likely to get to Series A, and we get there twice as fast (2 year vs 4 years).

Founders who work with venture studios are more likely to be successful and expend less stress and wasted effort along the way.

For an opportunity as large as scaling cellular agriculture, the first step is to partner with people who bring other pieces of the puzzle that are complementary to our own.

We’ve started with Lejjy from CULT Food Sciences. The former CEO and founder of a YC-backed B2B Cellular Agriculture business, Future Fields, and now CEO of one of the most forward thinking VC companies we’ve ever had the pleasure of working with, CULT is already building out a number of initiatives to scale the cellular agriculture industry (including The Cellular Agriculture Network of Excellence, their own Research, and a physical space in Canada).

“The venture studio provides a unique model that fits well with the overall strategy of CULT Food Science – it provides an avenue for new ideas and IP to be developed from the ground up with skilled experts and an eye for really pushing the boundaries of what has been done to date with cellular agriculture. Between CULT Food Science and InnoavtionStudio, we will be a driving force for new innovations in the industry over the next few years” – Lejjy Gafour, CEO of CULT Food Science.

Our next step is… you?

We’re seeking people who fit a broader vision of who a founder can be: a scientist, an inventor, or an operator, interested in building in a highly collaborative environment.

Up to three people will have the opportunity to receive a monthly stipend and work together with our Director of Venture Strategy, Abdul, over three to five months to identify, validate, and prioritize businesses in the opportunity areas outlined earlier. The top business/es will receive funding and support from InnoavtionStudio and CULT to launch and grow to the next stage of funding. You’ll be a part of the InnoavtionStudio Community in Brooklyn with full use of our biolab as well as access to InnoavtionStudio and CULT experts and mentors.

We envision someone who:

- Has a background in biotechnology or life sciences

- If an inventor, they have a potential technology that they’d like to see commercialized

- Has a strong point of view of what’s missing from the market and a vision for its economic viability

- Believes that impactful solutions are strong investments

- Prioritizes helping people at scale over one narrow focus

If you fit this description and want to talk more about being a part of our venture studio scaling cellular agriculture, come build with us! Get in touch at venturestudio[at]InnoavtionStudio[dot]com.

Clair Purcell has spent the past decade at the intersection of new business strategy, design, and technology. She leads the InnoavtionStudio Venture Studio, which partners with engineers, inventors, and experts to build businesses that positively impact the material world. Clair joined InnoavtionStudio after seven years at Boston Consulting Group’s Digital Ventures, where she built businesses and launched products in partnership with Fortune 500 companies in Asia Pacific, Europe, and North America. Prior to BCG, Clair founded and sold an e-commerce company.

Illustration by Nick Counter for New Harvest // CC BY-NC-SA 4.0